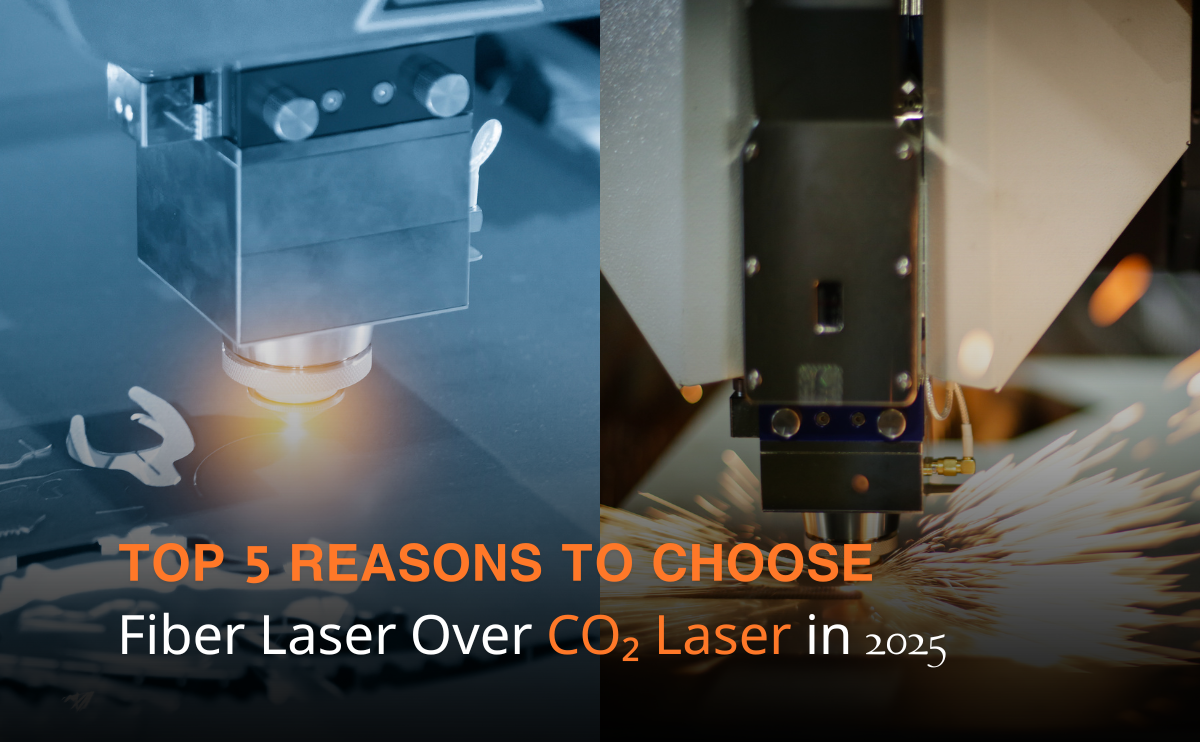

Introduction:

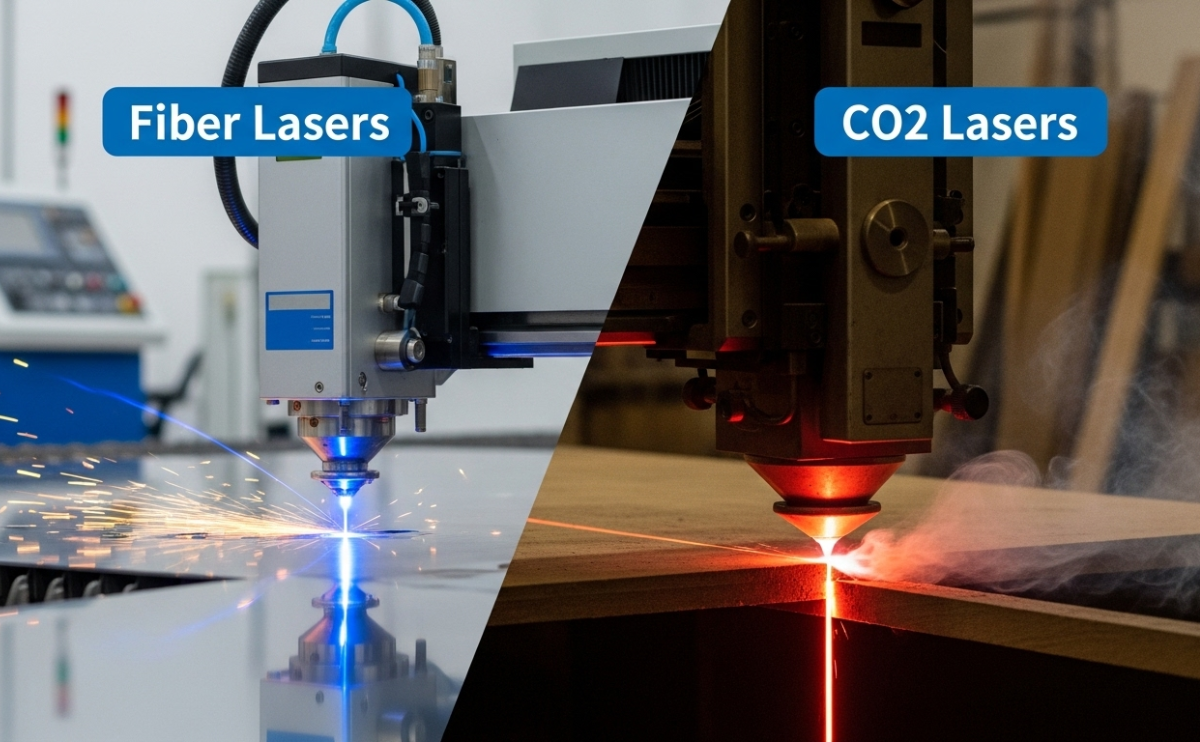

When it comes to laser marking and engraving, selecting the appropriate technology is crucial for achieving optimal results. At Lazer Point India, we offer both Fiber and CO₂ laser systems, each tailored to specific applications. Here’s a concise comparison to help you make an informed decision.

Fiber Laser

Marking and engraving metals like stainless steel, aluminum, and brass.

Advantages:

- High Precision & Speed: Ideal for intricate designs and high-speed operations.

- Low Maintenance: Solid-state design reduces the need for frequent upkeep.

- Energy Efficient: Converts more electrical energy into laser output, reducing operational costs.

Considerations:

- Material Limitations: Less effective on non-metals like wood or acrylic.

- Higher Initial Cost: Typically more expensive upfront compared to CO₂ lasers.

CO₂ Lasers

Best For:

Engraving and cutting non-metals such as wood, acrylic, glass, and leather.

Advantages:

- Versatile Material Compatibility: Can process a wide range of non-metal materials.

- Cost-Effective: Generally more affordable than fiber lasers.

- Superior Finish on Thicker Materials: Produces smooth edges on materials thicker than 5mm.

Considerations:

- Higher Operating Costs: Requires more power and maintenance.

- Slower Speed on Thin Metals: Not as efficient as fiber lasers for cutting thin metals.

Quick Comparison

| Feature | Fiber Laser | CO₂ Laser |

| Best For | Metals | Non-metals |

| Precision | High | Moderate |

| Speed | Fast | Moderate |

| Energy Efficiency | High | Moderate |

| Maintenance | Low | Higher |

| Initial Cost | Higher | Lower |

| Operating Cost | Lower | Higher |

Conclusion:

- Choose a Fiber Laser if your primary focus is on high-speed, high-precision marking and engraving of metals.

- Opt for a CO₂ Laser if you require versatility across various non-metal materials and are working with thicker substrates