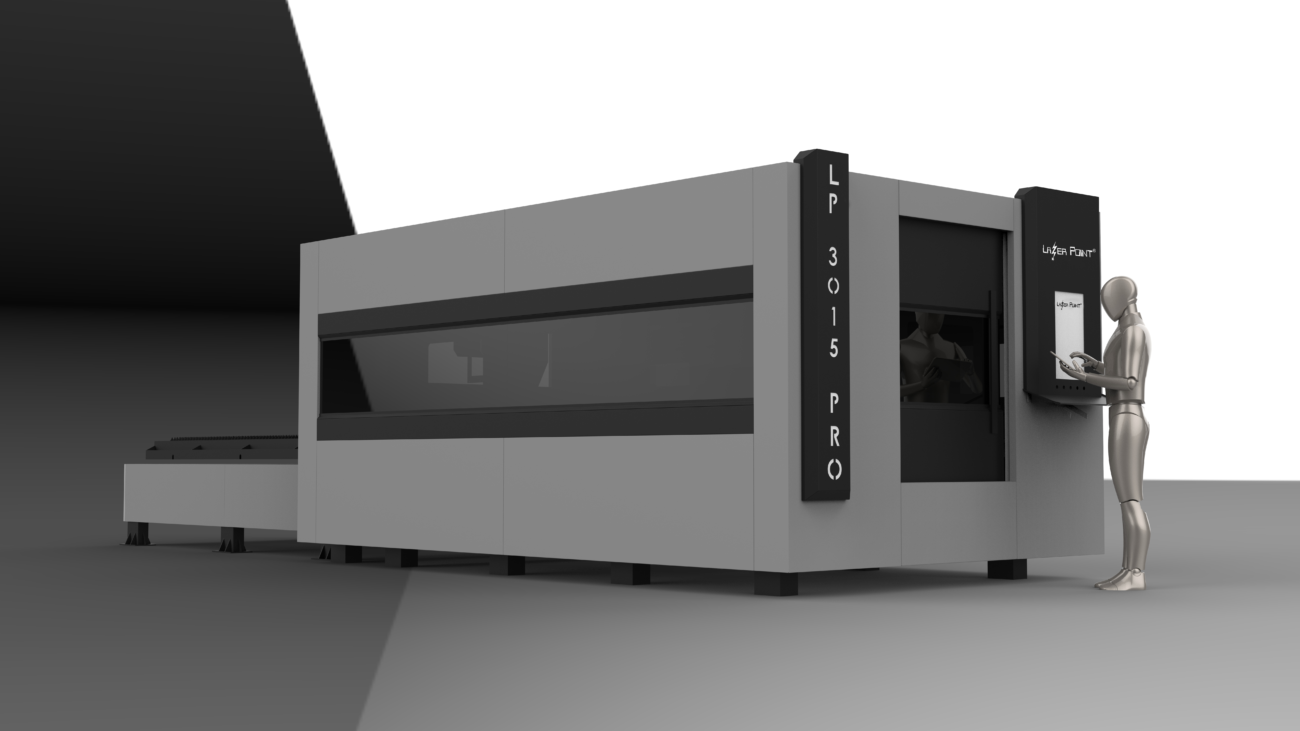

A Fiber Laser Cutting Machine Is A High-Precision Tool That Uses A Powerful Laser Beam, Generated By A Fiber Optic Cable, To Cut Through Materials With High Efficiency & Accuracy. It Is Known For Its Speed, Precision, & Versatility, Making It Ideal For Industries Like Metal Fabrication, Automotive, Aerospace, & Electronics. The Machine Offers Fast Cutting Speeds, Low Operating Costs, And The Ability To Cut A Variety Of Materials, Producing Smooth, Clean Cuts With Minimal Distortion. It Is Also Energy-Efficient & Requires Less Maintenance Compared To Traditional Cutting Methods.

MATERIALS TO CUT

- Stainless Steels

- Aluminiums

- Brass

- Carbon Steels

- Mild Steels

- Titanium

FEATURES

- Durable Rack-and-Pinion motion system.

- Light weight Gantry for high dynamics with synchronized dual servo motors.

- Top drag chain concept making machine compact & more safe.

- Back panel with Climate Control AC for electronics.

- Isolated HV protected control panel specially build.

- To work in unfavorable electrical conditions.

- Auto Focus Cutting Head.

- Machine dynamics 200 holes / min.

- Fireproof bellow for safety.

- Dust proof gas line for gas flow.

| Laser Source | IPG / RAYCUS / MAX / JPT |

|---|---|

| Working Area | 3000 x 1500 / 4000 x 2000 / 6000 x 2000 |

| Drive Motors | Yaskawa / Panasonic / FUJI AC Servo Motors |

| Cutting Head | Raytools/Ospri/ WSX/ Bochu Auto-Focus |

| Z Axis | 150 mm |

| Z Axis with Dual Pallet | 250 mm |

| LM Rails X, Y | HIWIN |

| Chiller | OEM / Hanli / S&A |

| CNC Controller | FSCut/ Raytool / Wihong |

| Rack & Pinion | YYC |

|---|---|

| Electronic Pressure Regulator | SMC / Fresto |

| Gas Line & Filter | SMC |

| Gearbox | YYC |

| Acceleration | 1.5 G |

| Position Accuracy | ≤ ± 0.05 mm / m |

| Repositioning Accuracy | ≤ ± 0.03 mm |

| Maximum Rapid Speed | 80 meters / min |

| Cutting Speed | 20 meters / min |