When it comes to laser technology in industries like signage, metal cutting, engraving, and manufacturing, one common question in 2025 is: fiber laser vs CO₂ laser — which one is better? While both have their uses, fiber lasers are fast becoming the go-to choice for businesses due to their speed, efficiency, and low maintenance.

If you’re planning to invest in laser machinery this year, here are five practical reasons why choosing a fiber laser over a CO₂ laser might be the best decision for your business.

1. Greater Cutting Speed and Precision

Fiber lasers offer significantly higher cutting speeds, especially when working with metals such as stainless steel, aluminum, brass, or copper. They use a solid-state laser source and a much finer beam, which allows for:

- Clean, precise cuts

- Faster processing times

- Minimal material wastage

2. Lower Operating Costs and Energy Efficiency

One of the biggest advantages of fiber lasers in the fiber laser vs CO₂ laser debate is their energy efficiency. Fiber lasers convert over 30% of electrical power into laser output, while CO₂ lasers convert only around 10%.

This means:

- Lower electricity bills

- Less heat generation

- Smaller cooling systems required

Also, fiber lasers have no moving parts or mirrors, reducing the need for constant maintenance or replacement parts — saving both time and money in the long run.

3. Minimal Maintenance, More Uptime

CO₂ lasers rely on mirrors, gas mixtures, and fragile components that require frequent upkeep. In contrast, fiber lasers are nearly maintenance-free.

- No need for regular alignments

- No gas refills or glass tubes

- Fewer breakdowns or production delays

As a result, your machine stays running longer without interruptions, ensuring higher productivity and less downtime.

4. Compact Design and Better Integration

Fiber laser machines are often smaller and more compact than their CO₂ counterparts. This is perfect for workshops or production lines where space is limited.

You also get:

- Easier integration into automated systems

- Flexible installation options

- Modern, clean design

This makes fiber lasers a great choice for modern factories looking for efficiency and aesthetics.

5. Long-Term ROI (Return on Investment)

Though fiber lasers might have a higher upfront cost, they quickly pay for themselves due to:

- Lower energy use

- Reduced maintenance

- Longer service life (often 3–4 times that of CO₂ lasers)

Think of it as a smart investment — by choosing fiber over CO₂, you’re saving money every month, increasing efficiency, and ensuring your equipment stays competitive for years to come.

Still Not Sure Which Laser is Right for You?

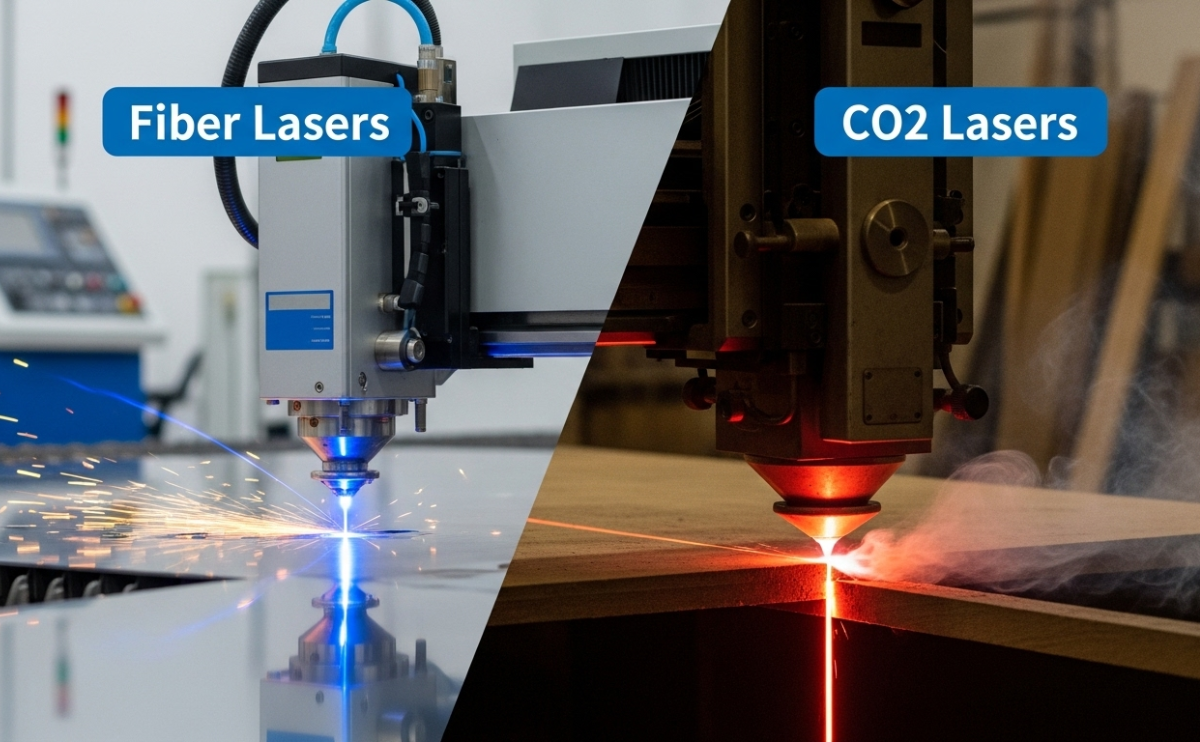

Both fiber lasers and CO₂ lasers have their place. CO₂ lasers are still useful for non-metal materials like acrylic, wood, and leather. But for 2025 and beyond, fiber lasers dominate when it comes to cutting and engraving metals efficiently.

Conclusion: The Smart Choice for 2025

Choosing between a fiber laser vs CO₂ laser in 2025 depends on your material, budget, and long-term goals. But for most industries working with metal, fiber lasers clearly win in speed, cost-effectiveness, low maintenance, and return on investment.

At Lazer Point India, we specialize in high-performance fiber laser machines built for today’s needs. Our team is always ready to guide you through the right choice for your business.

Ready to Upgrade?

Visit LazerPointIndia.in to explore our complete fiber laser machine range.

Have questions? Contact our experts today for a free consultation and quote.